Domestic breakthrough! Zenith’s thermally conductive MEMS gas sensor solves the industry’s pain point.

In the rapidly changing science and technology, sensor technology as the foundation of modern industry and intelligent life, the importance of more and more prominent. In the field of gas detection, MEMS gas sensors have become a market favorite due to their high sensitivity, low power consumption, small size and other significant advantages. 2024, the global gas sensor market size of about 4.25 billion U.S. dollars, is expected to reach 9.01 billion U.S. dollars in 2033, with China’s market growth is even more robust.

In this context, Guangdong Zenith Technology Co., Ltd. as an emerging force to emerge, with innovative technology and products, to promote the rise of domestic MEMS gas sensors, injecting new vitality into the industry, bringing new hopes and opportunities, helping the gas sensor market to a new height.

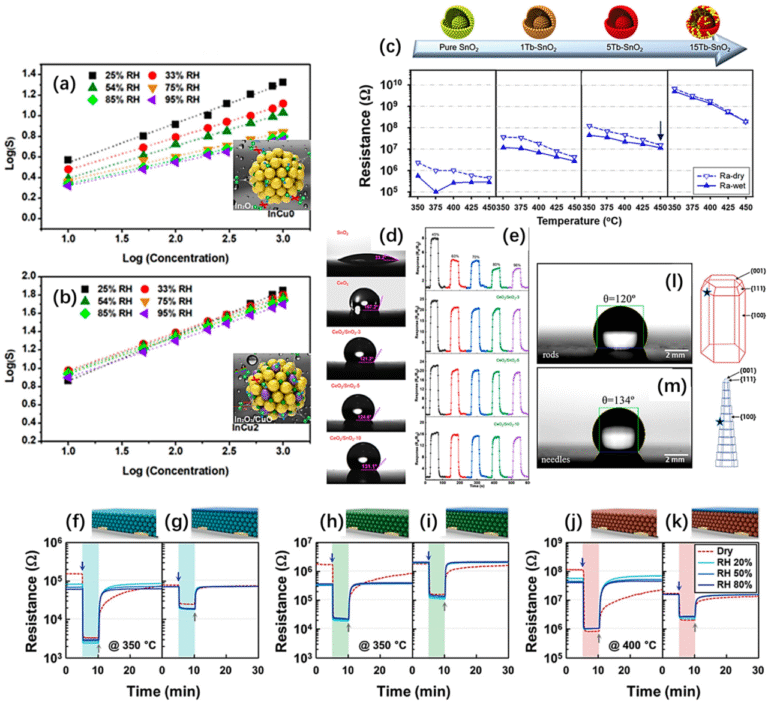

Guangdong Zenith Technology technical team has achieved fruitful results, published more than 100 papers in the top international SCI journals, and also set up a production line with an annual output of 1 million MEMS gas-sensitive sensor chips, which significantly reduces the cost and is expected to break the monopoly of foreign technology. R & D investment continues to increase, has invested about 45 million yuan, the future plan of annual R & D investment accounted for more than 8%, a number of R & D indicators clear, aspire to establish provincial and national laboratories. The company has a wealth of intellectual property reserves, has been awarded a number of patents, soft writings, patents covering the whole process of the product. The core team members are all industry elites, covering experts in various fields, specializing in scientific research, production, algorithms, hardware and operation, etc., providing solid technical support for the development of the enterprise.

Core Products and Technologies

In the gas sensor industry, traditional gas sensors generally have high price, short life, lack of stability, cross false alarms and other problems, seriously restricting the development of the industry. Guangdong Zenith Technology Co., Ltd.’s thermally conductive MEMS gas sensor has become the key to break the game.

At present, the high-end digital integrated gas sensor market has long been monopolized by Western countries, domestic enterprises face technical blockade and high import costs. With strong technical strength and innovation ability, Zenith has successfully developed MEMS gas sensors with independent intellectual property rights, which breaks the foreign technical barriers, significantly reduces the production cost, greatly improves the competitiveness of the product market, and is of great significance in the domestic substitution.

Zenith’s thermal conductive gas sensor has significant advantages. It is low cost, small size, long life, can work stably in harsh environments, suitable for large-scale deployment, effectively solving the industry’s pain points, and better meet the market demand. This is due to its innovative technology:

chip – 3D micro-cavity array design: to achieve high sensitivity and high selectivity.

Thermal conductive materials: selectivity to the thermal diffusion of the target gas to enhance detection accuracy.

Mass production process: Matching design process to ensure product consistency.

Auto-calibration: Multi-modal sensor integration to enhance the intelligence of the sensor.

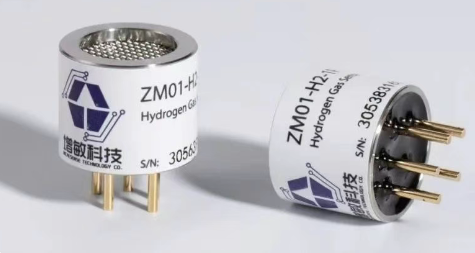

Zenith has a wide range of core products, including hydrogen, methane, carbon dioxide and other sensors. They are widely used in hydrogen energy industry chain, natural gas extraction, environmental monitoring, chemical industry, medical treatment and semiconductor manufacturing. The company benchmarks the international advanced third generation gas sensor technology research and development, product performance is excellent, can replace imports, and strongly promote the development of China’s gas sensor industry .

Application Scenarios and Solutions

Hydrogen sensors: for safety monitoring of the hydrogen energy chain.

Methane sensors: for safety monitoring of natural gas extraction and transportation.

Carbon dioxide sensors: for indoor air quality monitoring and industrial process control.

Hydrogen sulfide sensors: for safety monitoring in petrochemical and wastewater treatment.

Tetrahydrothiophene sensors: for natural gas odorant detection.

Sulfur hexafluoride sensor: for insulation gas monitoring of power equipment.

Major Customers and Industries

Zenith’s MEMS digital gas sensors are widely used.

1、civil aviation field: cooperation with the Civil Aviation Flight School of China, the use of thermally conductive MEMS digital gas sensor technology, co-development of hydrogen fuel cell real-time safety monitoring system.

2、oil and gas field: with PetroChina Southwest Oil and Gas Field Branch, based on sensing technology, jointly developed gas odorant and hydrogen sulfide concentration detection system, to enhance the safety of gas use.

3、Industrial field: such as petroleum, chemical industry, etc., accurate monitoring of gas data to ensure production safety and efficiency.

4、Daily life: to help environmental protection, transportation and other areas of monitoring, to bring safety and convenience to our lives.