Prof. Xiaolong Liu, Sun Yat-sen University – Sniffing out Lung Cancer: Frontier Advances in Metal Oxide Semiconductor Gas Sensors

Article Introduction

In the field of modern medical diagnosis, early detection of lung cancer is crucial for improving the survival rate of patients. However, traditional diagnostic methods, such as sputum cytology, histopathology and imaging, are often invasive, costly and have limited resolution. With the development of breath analysis technology, a novel non-invasive diagnostic tool, metal oxide semiconductor (MOS) gas sensors, has attracted much attention due to its high responsiveness and fast response time to volatile organic compounds (VOCs). This article written by Prof. Xiaolong Liu’s team at the School of Materials, Sun Yat-sen University, and published in Chemosensors, reviews the application of MOS gas sensors in lung cancer diagnosis, discusses their working principles, material selection, performance optimization strategies, and challenges, and provides valuable references for future research and clinical applications. The article firstly introduces the epidemiological background of lung cancer and the limitations of traditional diagnostic methods, followed by an in-depth discussion of the working principle of MOS gas sensors, including the mechanism of gas molecules interacting with the MOS surface. Then, the article focuses on the material selection for MOS gas sensors, especially the research progress of n-type semiconductor materials such as SnO2 and ZnO. In addition, the article details strategies to enhance the performance of MOS gas sensors, such as micro/nanostructure design, surface modification, and humidity resistance improvement. Finally, the article discusses the application of MOS gas sensor arrays and pattern recognition techniques in breath analysis, and provides an outlook on future research directions.

Research process and results

1.Working principle of MOS gas sensor

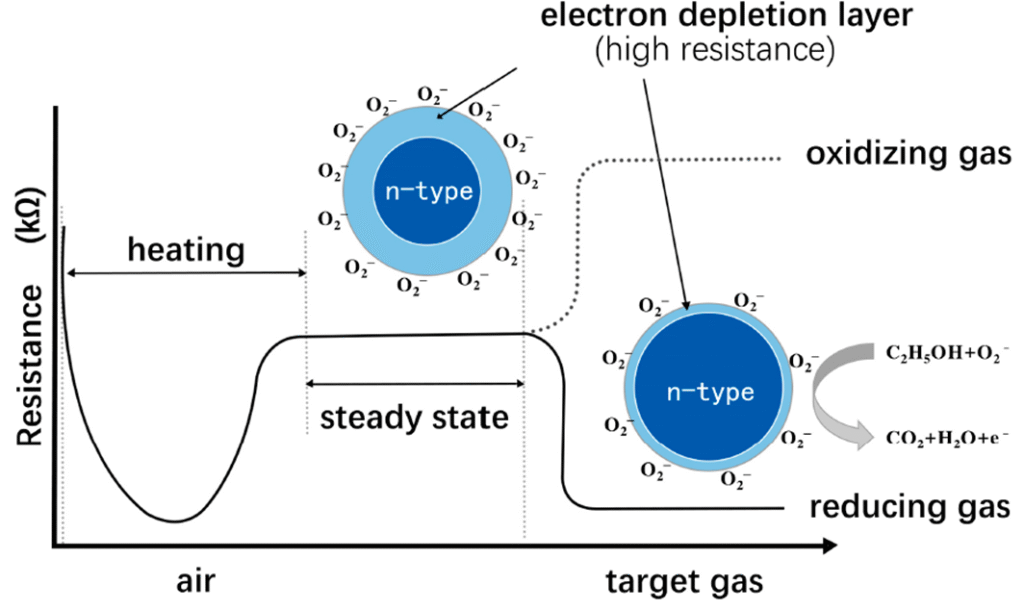

The working principle of MOS gas sensor is based on the conductivity change of the sensing material in different gas environments to detect the target gas, which involves a variety of theories, such as chemisorbed oxygen model, grain boundary barrier model, bulk resistance model, and space charge layer model, and the key lies in the interactions between the gas and the material surface. Taking n-type SnO2 as an example, O2 in the air is adsorbed on the surface to form chemisorbed oxygen species (O2-, O-, O2-) when heated, and at the same time, an electron depletion layer is generated at the contact interface of the MOS grains to increase the resistance; when a reducing gas (e.g., ethanol) is introduced, it reacts with the chemisorbed oxygen species to release electrons, and the resistance decreases; and the introduction of oxidizing gases further depletes the electrons in the sensing layer and increases the resistance (Fig. 1). The introduction of oxidizing gases further depletes electrons from the sensing layer and increases the resistance (Fig. 1). Rational experimental designs can be based on existing materials to realize the enhancement of their gas-sensitive properties. For example, reducing the MOS grain size to near or less than twice the Debye length can significantly improve sensitivity. However, too small a particle size can lead to aggregation of nanoparticles, which makes it difficult for the internal particles to participate in the reaction, resulting in a reduction of gas-sensitive properties. Therefore, specific nanostructure design and “second-phase modification” are crucial for improving the gas-sensitive performance of MOS materials.

Schematic diagram of n-type MOS sensitive material detection principle

2.Material selection and performance optimization strategies for MOS gas sensors

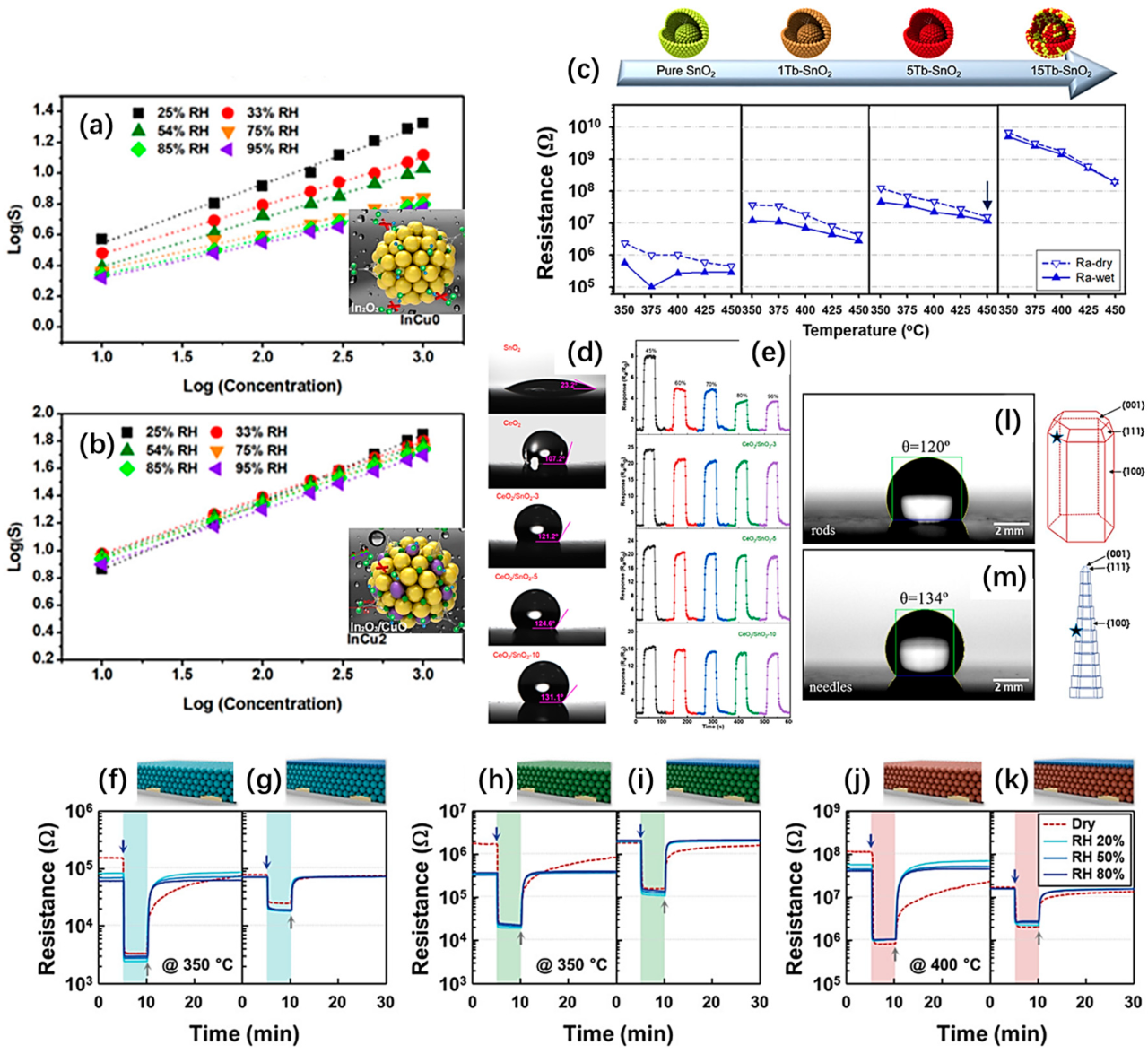

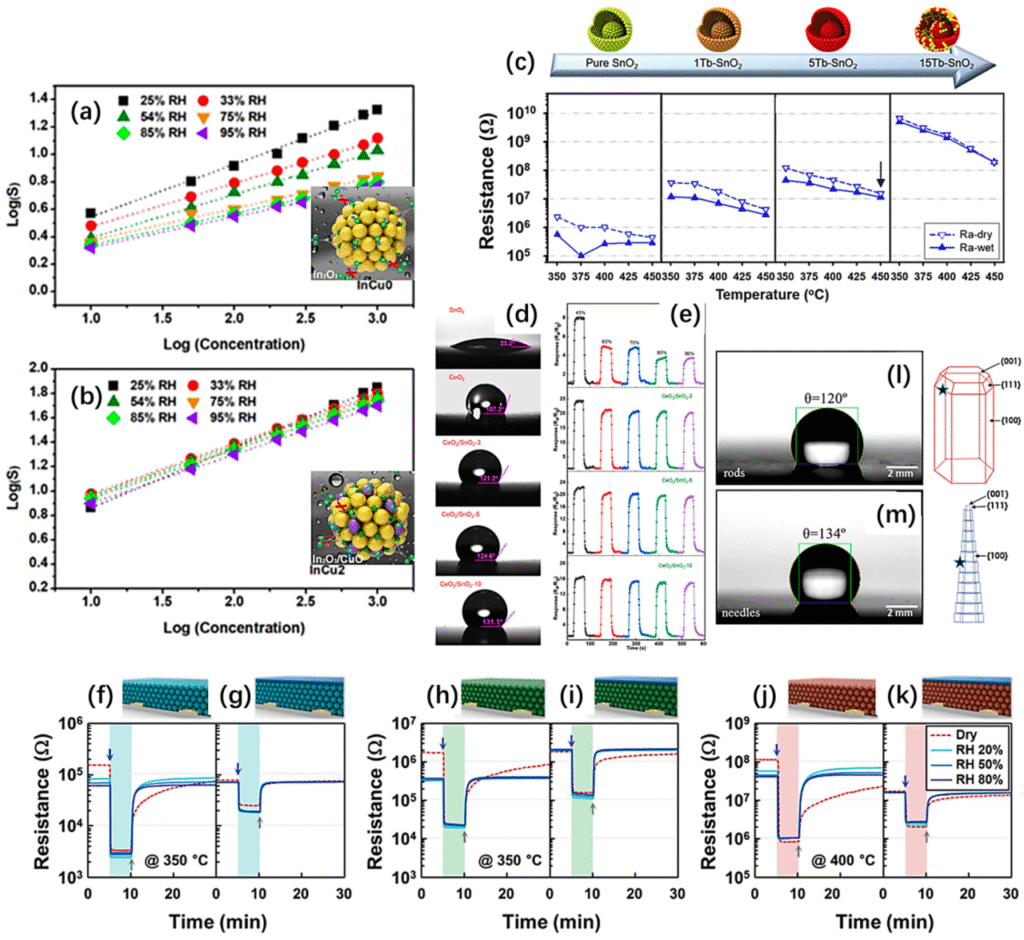

In the past decades, the n-type semiconductors SnO2, ZnO, TiO2, WO3, In2O3, Fe2O3, and CeO2, and the p-type semiconductors CuO, NiO, Co3O4, Cr2O3, and Mn3O4 have been widely investigated as MOS materials. properties have been widely studied. Especially, SnO2 and ZnO have become the hotspots of research because of their high stability and electron transfer ability. Different morphologies of these materials, such as nanoparticles, nanowires, and nanotubes, have significant effects on the gas sensing performance. To improve the performance of MOS gas sensors, researchers have adopted various strategies, including optimization of the micro/nanostructure of the materials, surface modification, and improvement of humidity resistance. For example, the responsiveness and selectivity of the sensor can be significantly improved by introducing noble metals such as Pd and Pt. In addition, the sensitivity and responsiveness of the sensor can also be improved by designing specific nanostructures such as hollow structures with multiple shell layers. The high humidity environment in the exhaled breath negatively affects the performance of MOS gas sensors, so improving the humidity resistance of the sensors is crucial to achieve accurate diagnosis. Researchers have improved the humidity resistance of MOS materials by introducing strongly hydrophilic or hydrophobic materials, low valence doping, and exposing special crystalline surfaces (Figure 2). Fig. 2. Improving the humidity resistance of MOS.

Improving the Humidity Resistance of MOS

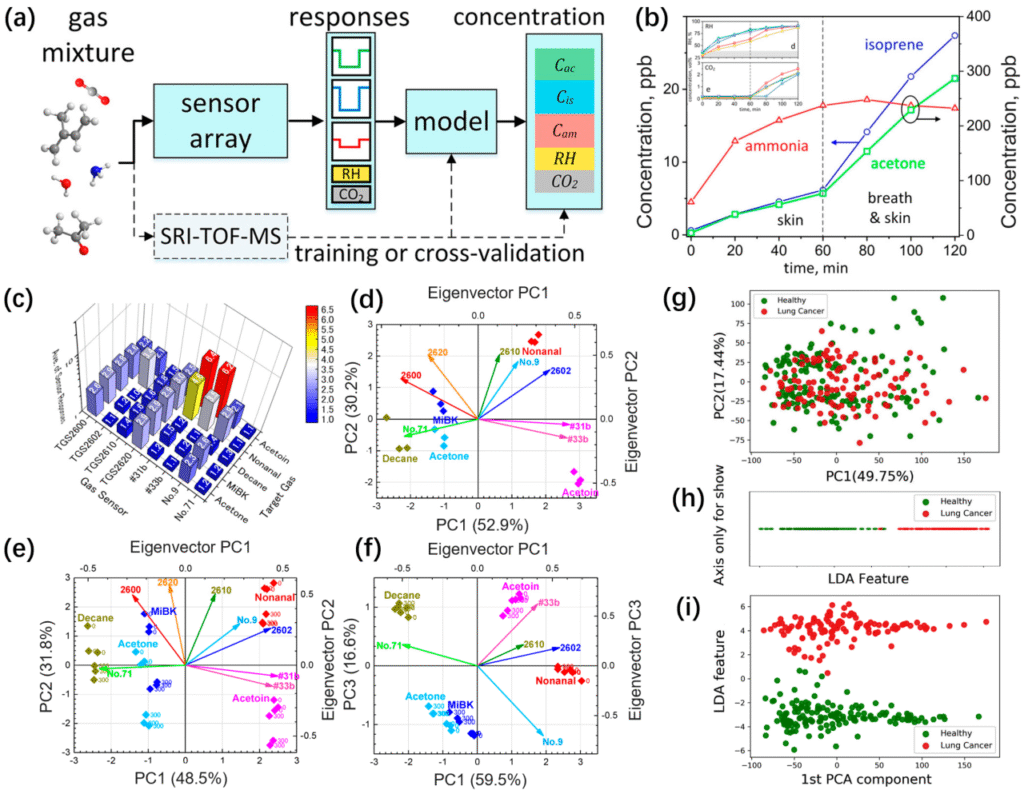

3.MOS gas sensor arrays and pattern recognition

Since a single VOC has not yet been identified as a lung cancer-specific biomarker, and the complexity of the VOC composition in exhaled breath, the many interferences, and the low concentration of biomarkers make it difficult for a single MOS material sensor to meet the detection needs. Unlike single MOS sensors that are highly selective for specific gases, each sensor in the MOS array does not need to be highly selective for a specific analyte, but rather records the response of exhaled breath with various MOS to form a “respiratory imprint” that can be analyzed by existing statistical models to identify low-concentration biomarkers for lung cancer, such as VOCs. The sensor array effectively overcomes the problem of insufficient selectivity of single MOS sensors, but the use of too many sensors will result in redundancy of information due to the broad-spectrum response of MOS, which will increase the difficulty of the identification system without improving the accuracy, so it is necessary to select the appropriate composition of the MOS sensor array according to the detection requirements, and to develop more accurate and efficient pattern recognition algorithms (Fig. 3). Principal component analysis (PCA) and linear discriminant analysis (LDA) are commonly used dimensionality reduction algorithms to improve classification accuracy, reduce computational complexity, and facilitate visualization of the output results.MOS gas sensor arrays have a great potential for lung cancer diagnosis, but environmental factors (e.g., temperature and humidity) can affect their accuracy and reliability, so new materials and fabrication technologies need to be explored and more optimization algorithms (e.g., deep learning algorithms) need to be introduced to improve the accuracy and reliability. In the future, it is necessary to explore new materials and fabrication techniques, and introduce more optimization algorithms (e.g., deep learning algorithms) to increase the gas recognition rate, and improve the gas recognition algorithms by combining machine learning and artificial intelligence techniques.

Sensor arrays and pattern recognition

Article Summary

This paper provides a comprehensive review of the research progress of metal oxide semiconductor gas sensors in lung cancer diagnosis. The high mortality rate of lung cancer highlights the urgency of early diagnosis, and breath analysis provides a new way for early screening of lung cancer, in which MOS gas sensors are of great significance.MOS gas sensors have a number of advantages, and their development has witnessed the continuous evolution of technology. In terms of the working mechanism, multiple theories explain the principles of conductivity change, based on which the performance of single MOS gas sensors can be enhanced by optimizing microstructure, noble metal modification, and other strategies, such as multiple structural optimization of the material significantly improves the gas-sensitive performance, and the noble metal modification not only enhances the response and selectivity, but also reduces the detection limit, while a variety of methods effectively improves the humidity resistance. The application of sensor arrays and pattern recognition technology overcame the problem of insufficient selectivity of single sensors, and the effective detection of lung cancer-related VOCs was achieved through the combination of different sensors and optimization of algorithms, but it still faces the challenges of uncertainty of biomarkers, material performance to be improved, algorithms to be optimized, and equipment to be improved in clinical applications. In conclusion, although MOS gas sensors have made some progress in the field of lung cancer diagnosis, multidisciplinary collaborative efforts are still required to realize large-scale clinical applications. In the future, it is necessary to clarify the biomarkers of lung cancer breath, improve the performance of materials, develop advanced algorithms, optimize the design of equipment, and deeply understand the gas sensitivity mechanism, in order to promote the wide application of this technology in the early diagnosis of lung cancer, and bring new breakthroughs in the prevention and treatment of lung cancer.